-

$ 8 +

Over 8 years implementing

and managing technology. -

11,658 +

Over 8 years implementing

and managing technology. -

134 +

Over 8 years implementing

and managing technology.

Challenges & Opportunities

A major 3PL had found success by providing first-class service to its clients. However, the company and its major client had been experiencing errors and inefficiencies. This was due to the lack of warehouse modernization, causing crucial implications for its client’s business. The 3PL contacted Cyzerg to assess its warehouse operations and systems and identify challenges and opportunities.

After assessing the 3PL’s operations, Cyzerg discovered that the company had a legacy system that was preventing the automation of many repetitive warehouse tasks. Additionally, consistent errors were found on customer reports since the 3PL manually created warehouse receipts from purchase orders. Furthermore, the 3PL experienced errors and inefficiencies due to the lack of integration between its systems and its customer’s systems. Finally, the 3PL’s receiving process was slow due to the manual measurement of cargo dimensions and weight.

Solutions

After completing the assessment and identifying the 3PL’s challenges and opportunities, Cyzerg recommended the 3PL to undergo warehouse modernization.

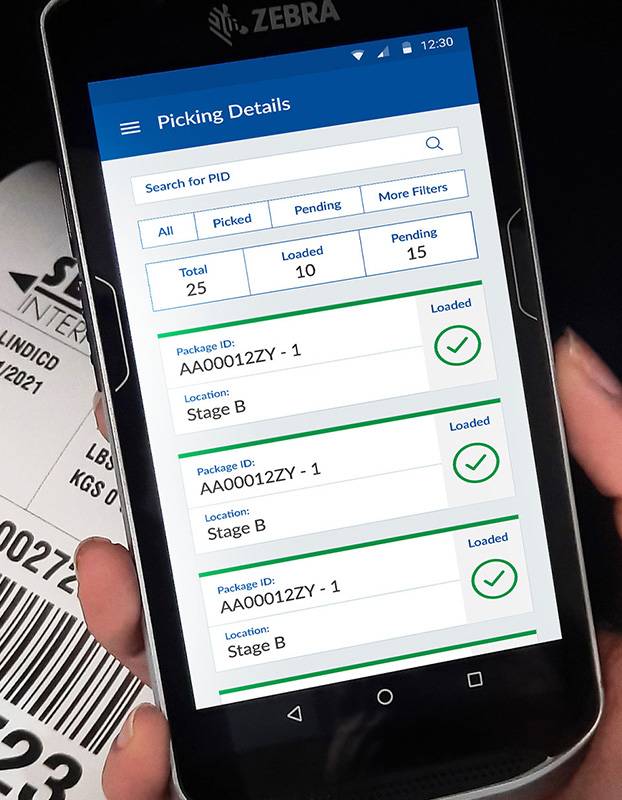

Cyzerg developed a custom in-transit WMS that allowed the 3PL to automate the creation of warehouse receipts from purchase orders and customer-related reports. Additionally, workflows were implemented to autogenerate warehouse tasks based on cargo status and other triggers. The custom in-transit WMS was also developed with an open API to offer full integration capabilities to all its customers. Lastly, Cyzerg automated the parcel and pallet dimensions, weight, and image-capturing process to address its slow receiving process.

To reduce the investment risk, Cyzerg created a proof of concept to validate all of the above solutions.

Results

Once the 3PL validated the proof of concept, the custom in-transit WMS was developed by Cyzerg. After system testing and data migration, the custom software was launched.

The 3PL’s reporting accuracy increased to 99% by automating the PO-to-WR creation and report generation. Additionally, the 3PL eliminated approximately 960 man-hours per month for a total savings of $205,000 of operating cost per year related to data entry and report generation. Moreover, the custom in-transit WMS was implemented with workflows to automate many repetitive warehouse tasks. Finally, the 3PL’s receiving capacity significantly increased by 113% due to the automation of its weighting and dimensioning process.

The 3PL was able to undergo warehouse modernization and address the errors and inefficiencies affecting the business and its customers. These solutions and results allowed the 3PL to operate more efficiently and continue providing first-class service to its clients.

Boost Efficiency Through Cyzerg’s Custom Software

Cyzerg will never sell, rent or otherwise distribute your information. Click here to read our full privacy policy.