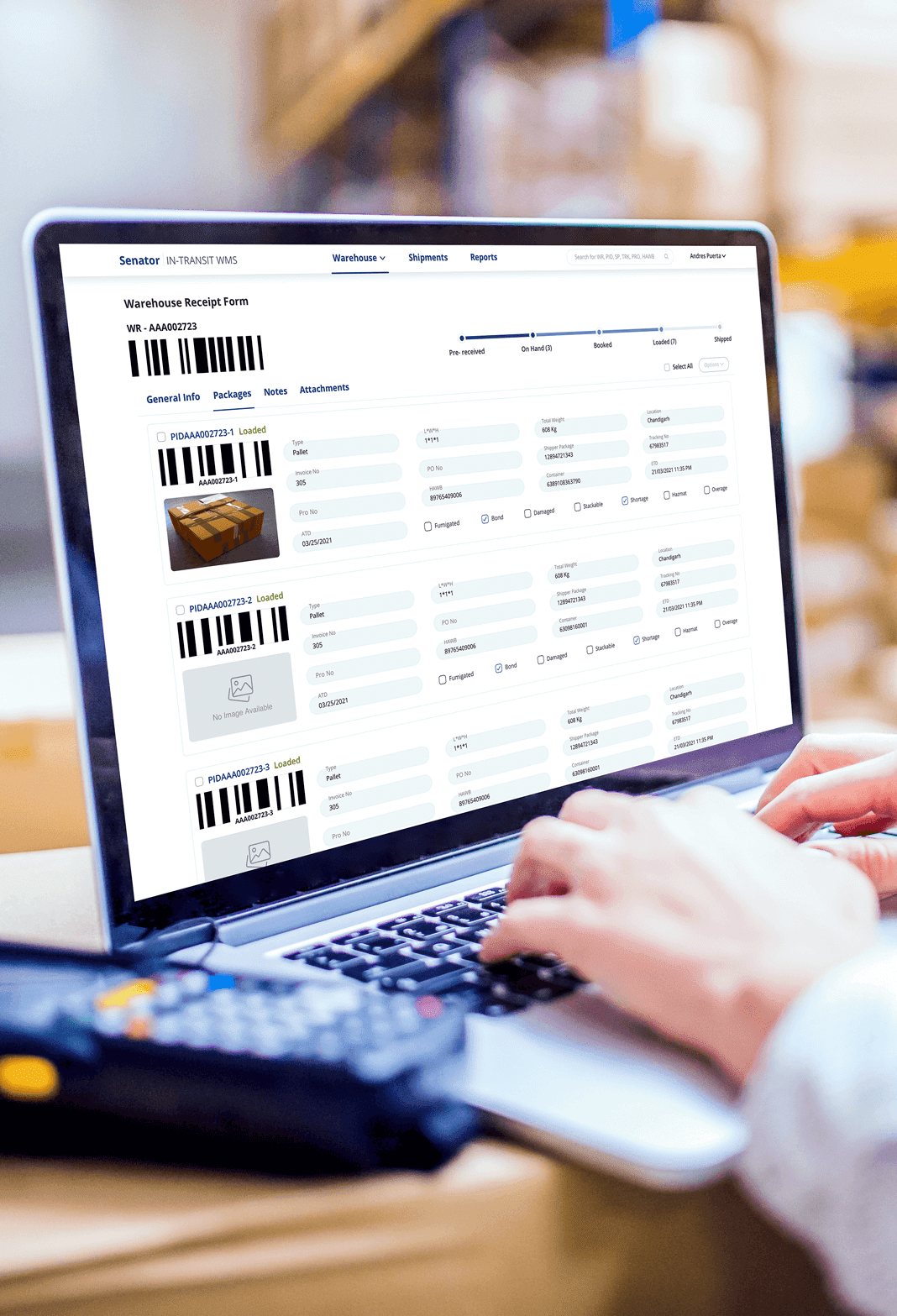

Space Management Systems

These systems help you maximize space by optimizing warehouse layout and storing cargo in the most appropriately sized location.

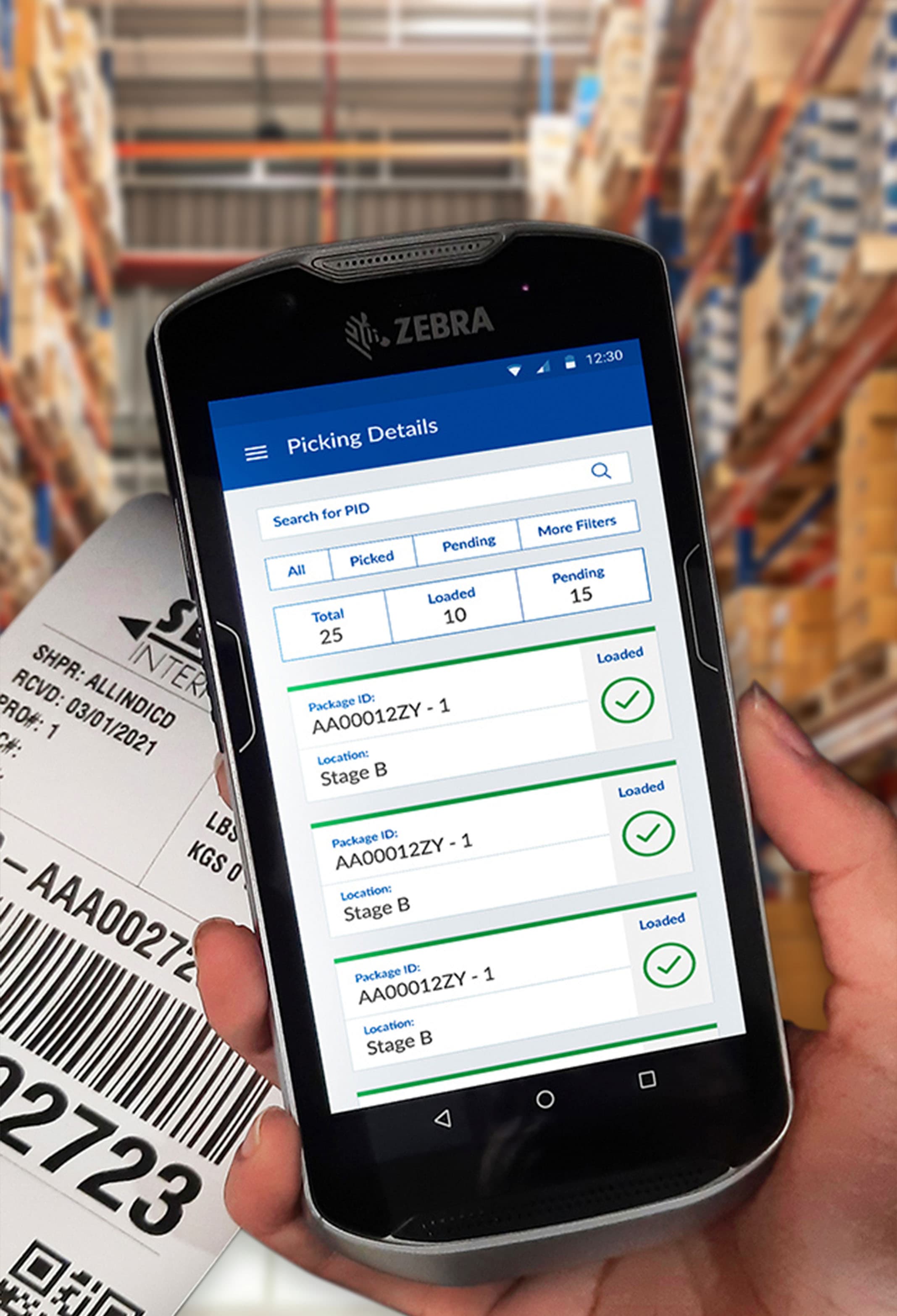

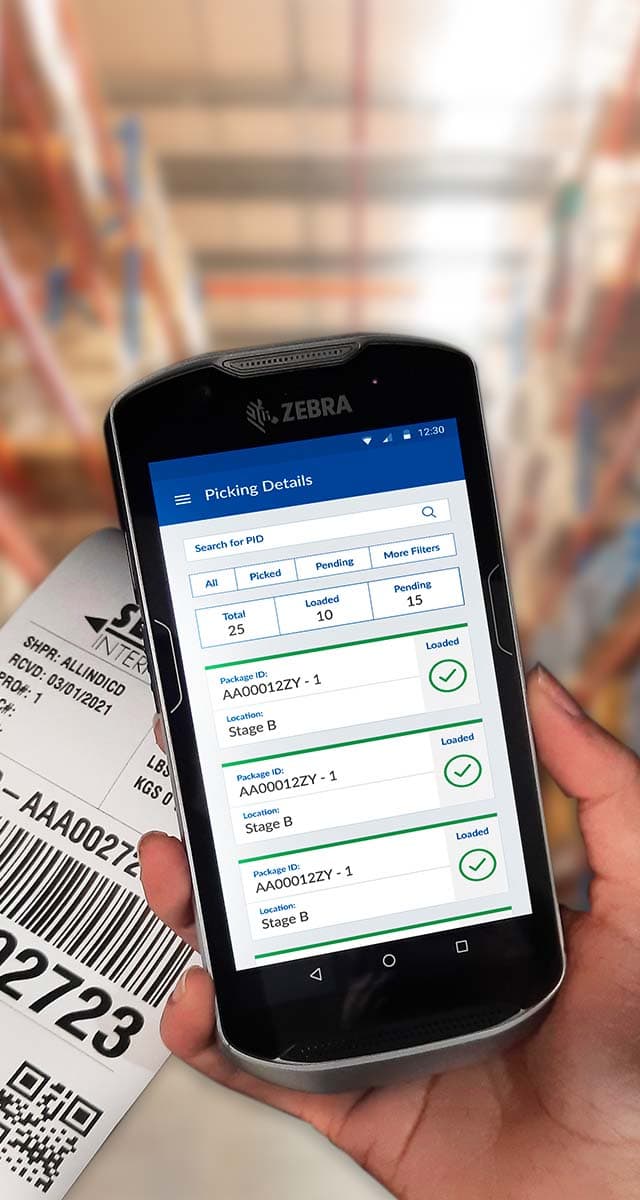

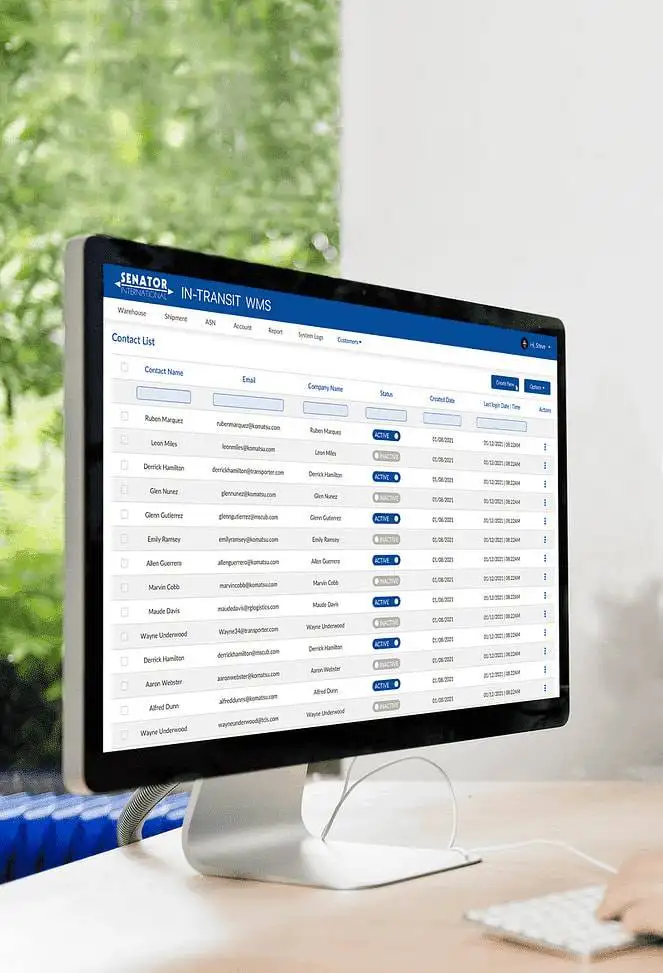

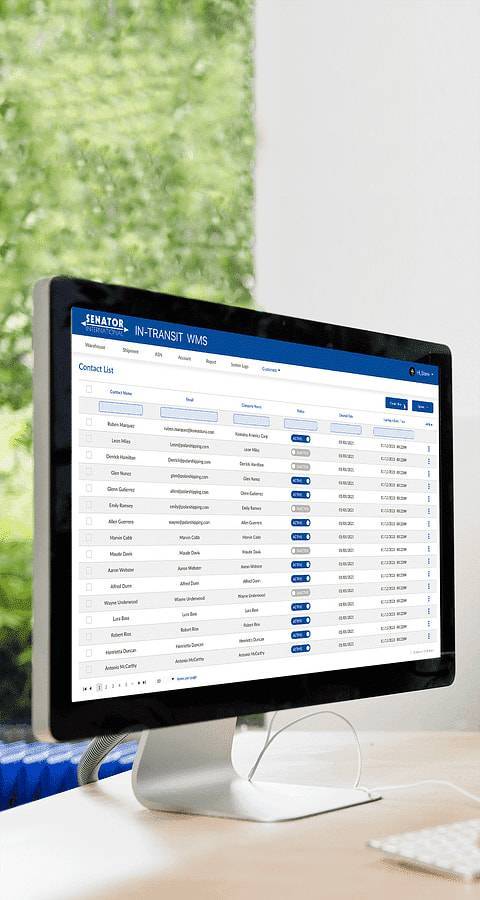

Implementing custom warehouse technology can help you address specific challenges and opportunities that off-the-shelf solutions cannot solve.

By having a unique warehouse solution, your company can gain a business differentiator over competitors, which you can harness to catapult your business into the future.

Cyzerg will never sell, rent or otherwise distribute your information. Click here to read our full privacy policy.